Part 2: Changing the system as business realities change

Hands up all those who have started implementing an ERP system and not had to deal with changes as the project progresses. No one? I am not surprised. Has anyone gone live with an ERP project and never had any changes afterwards? The reality of any ERP project is that scope changes occur during the project, and after going live it is guaranteed that there will be more requirement changes.

In my previous blog, I discussed how integrated BPM (business process management) and ERP could provide a visual representation for designing and building an ERP, referring to my personal experience of having built a house. The second part of the story is about changing the plans when new ideas or new realities come up.

With my house we had extensive discussions with the architect during the design phase and we were confident that everything had been covered. But when we spoke to the builder he made additional suggestions and noticed some things that had not been considered. Using the blueprint drawings, we could decide on the changes needed, assess the effects on the building and the costs, and then make alterations to the drawing that everyone agreed with. It was a clear and understandable approach to taking on new ideas and changing plans even after everything had been agreed.

The same process happens in ERP implementations. Organizations often spend a good deal of time working on the design of the ERP application using skilled (and expensive) consultants to help them. This they believe will ensure they have got it right before the implementation starts. However, no matter how good the team, the fact is that issues can be over-looked, or valid change requests suddenly appear which had not been considered earlier.

In the past this was a problem because the ERP planning process assumed stability, and ERP systems were geared towards controlling data and automating processes. Flexibility and handling change were not priorities. Of course the world has changed and we now expect our software to be adaptable. For enterprise software, with its high level of inter-connected functionality and degree of complexity, this has been a challenge … until the advent of integrated BPM and ERP. With this integrated process toolset, new ideas and issues can be raised after planning is finished, and re-planning, review, approval and documentation can be managed more easily and clearly.

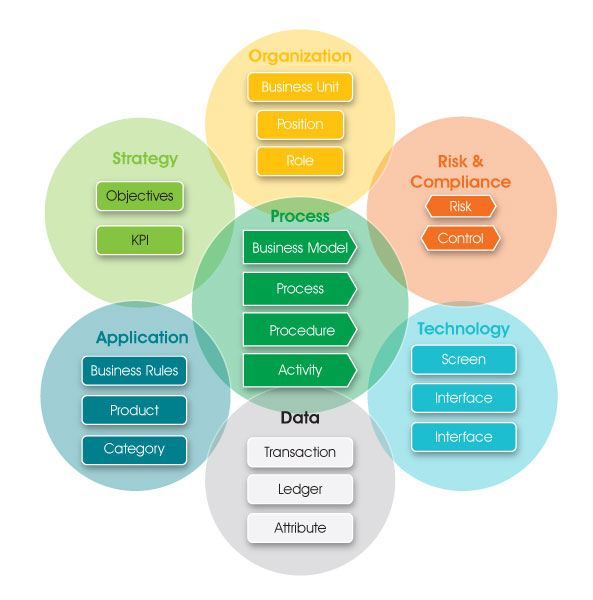

This concept of a model-driven ERP system is now possible using SYSPRO Process Modeling (SPM). Model-driven architecture has been around for 10 years, and is recognized as the most effective way to manage and optimize business processes, especially in a volatile environment. SPM helps in process management from high-level ‘Core Processes’, to actual ‘End-to-end’ processes, right down to activities and screens. For each level, this is integrated with the organizational structure, technology, data, and SYSPRO’s supported business processes.

This allows the organization to see how everything is inter-connected, and also to see how changing one element impacts on other areas of the model.

Hopefully the days of referring to ERP software as ‘monolithic’ are coming to an end. Changes to an ERP system should be expected and planned for because there are many aspects that can change. If you have been through more than one ERP implementation, particularly from the user perspective, what was your experience of making changes to the system? What would have made it easier?

In the next part of this blog series: Having the right approach and attitude to an ERP implementation.